Since its establishment in 2001, Komman has been committed to the development, production, and sales of commercial bus air suspension systems. The production and sales of bus air suspension system/independent air suspension system products have been among the best in the domestic industry for many consecutive years. In 2008, the company passed the ISO/TS 16949 management system certification and was the first company in China's air ride suspension industry to pass the certification. As of the end of 2020, Komman has applied for more than 60 patents, including 4 invention patents and more than 50 utility model patents. We have a strong air suspension bus technical background, undertook 3 national-level scientific research projects, participated in the preparation of 3 industry standards, and drafted and formulated 2 industry standards. Contact us for more bus air suspension diagrams and air ride suspension cost.

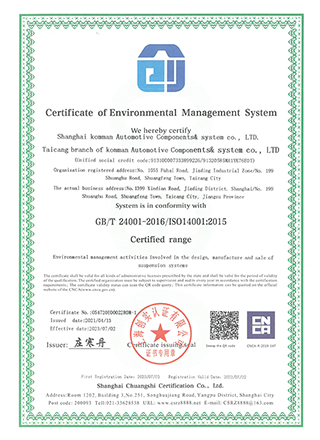

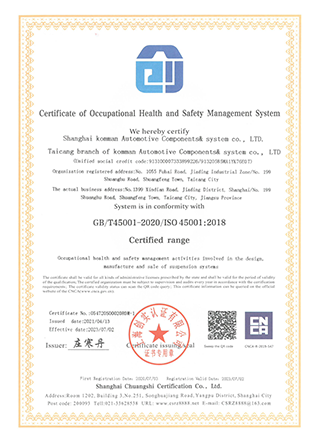

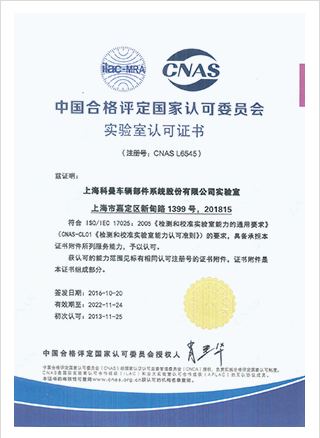

Adhering to the quality policy of "leading technology, leading quality, leading service", the company has established a strict and standardized quality management system to ensure the orderly air ride suspension production of the company and the stability of product quality. In 2008, the company passed the ISO/TS 16949 management system certification and was the first company in the custom air ride suspension industry to pass the certification. In 2011, 2014, and 2018, the company successfully passed the recertification work of this certification.

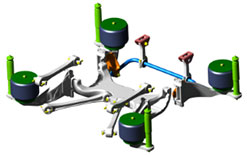

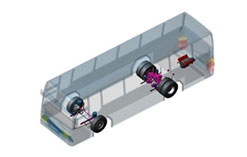

3D design

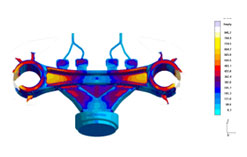

As a big and high-tech air suspension manufacturer in China, Komman uses 3D interference analysis technology to truly simulate the positional relationship between the parts during the jump, jump, and roll of the axle, avoiding the interference of parts during the product operation, improving the design quality, and optimizing the design solution of the air ride suspension for buses.

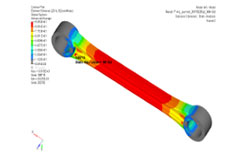

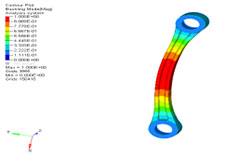

Finite element analysis of the part structure

Through finite element analysis technology, the working stress, strain, and displacement of the designed product can be grasped, and the optimized design and lightweight design of structural parts can be carried out at the same time to improve the reliability of the air ride suspension for sale and reduce the product development cycle and development costs.

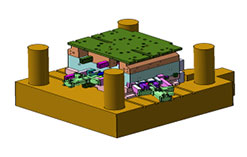

System dynamics analysis

Use ADAMS system dynamics simulation software to analyze the movement relations and dynamic forces of various air lift suspension kit parts of the system during the movement process, and optimize the system design scheme.

Komman has introduced RDM, an R&D management system, and PDM, a product data management system. Based on APQP, the R&D projects are grouped and hierarchically managed, and the relevant departments are coordinated to achieve all-around real-time monitoring of the project. At the same time, Komman air ride suspension for sale uses AUTOCAD, SOLIDWORKS, ADAMS, CATIA, and other professional system analysis software to conduct multi-dimensional analysis of products through finite element analysis, system dynamics analysis, control system analysis, and other technologies to ensure the quality of the bus air suspension diagram design solution.

Through 20 years of exploration and research, Komman independent suspension has accumulated first-class domestic commercial vehicle customers, such as Foton, HIGER, Yaxing Commercial vehicle, Zhongtong Bus, BYD, Suzhou King Long, and other high-quality customers. Our products are exported to many counties and have been unanimously recognized by our customers.